TWIN TRAIN Workshop

Solutions

TwinTrain Workshop

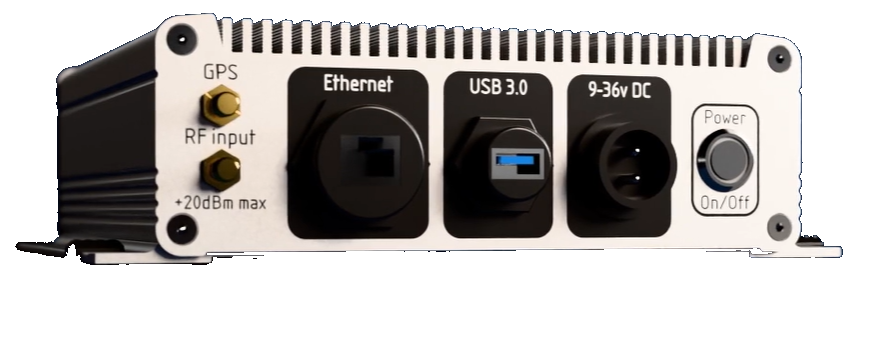

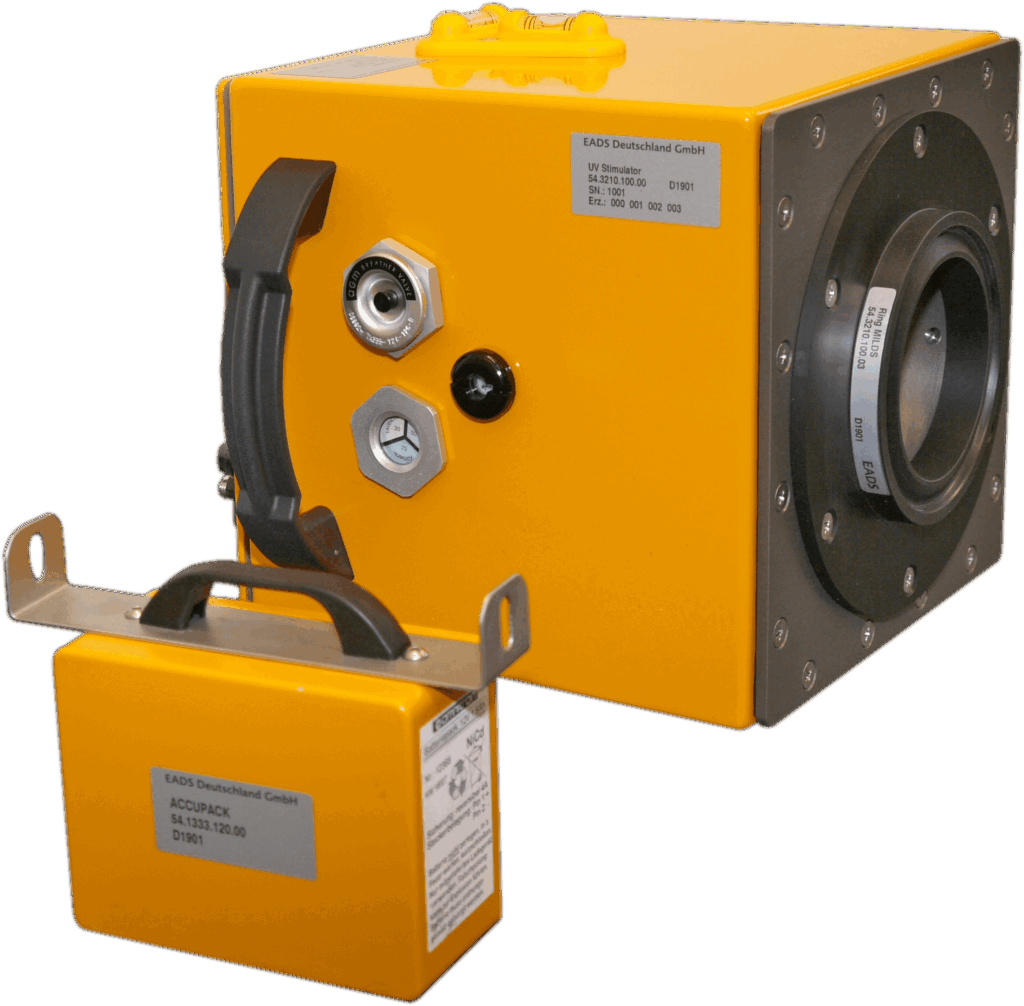

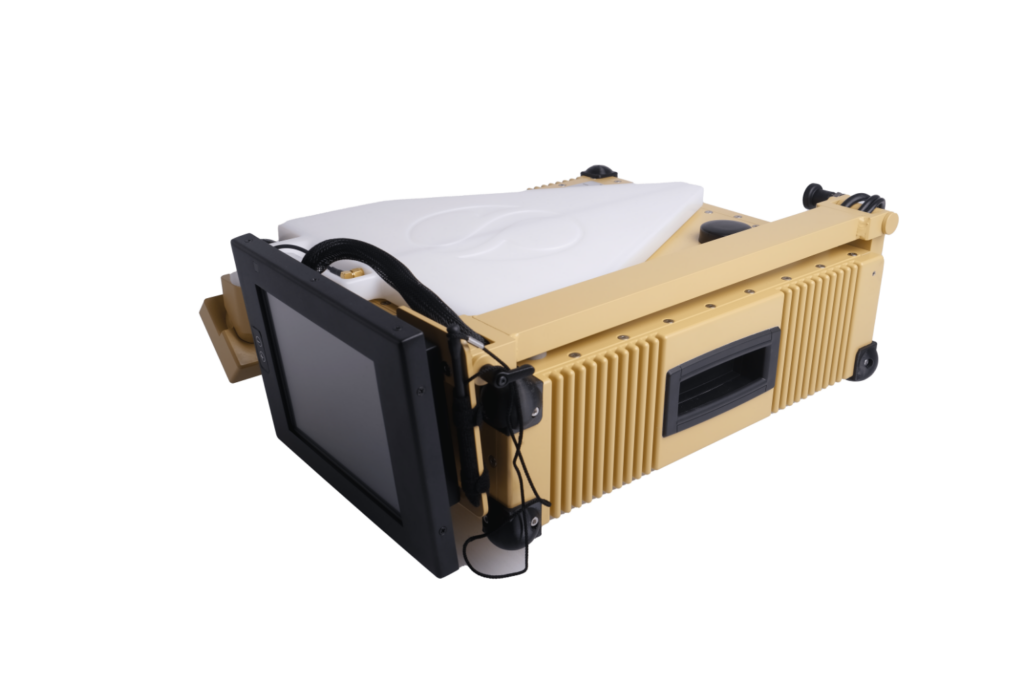

Spherea’s TwinTrain Workshop is a standardized solution for testing a wide range of electrical and electronic components in rail vehicles. Despite their varied functions, many components share similar interfaces. The system uses generic measurement and stimulation electronics, requiring only an adaptation cable to test different Devices Under Test (DUTs). This enables fast, flexible deployment of new applications.

The universal test concept offers a consistent environment that adapts to evolving needs, ensuring safety and quality through comprehensive testing. DUTs can be tested both on the vehicle and off it, whether installed or standalone.

Depending on the application, test scopes range from basic functional checks for quality assurance to advanced diagnostics and troubleshooting. With long-term service options and high flexibility, TwinTrain Workshop is a sustainable, future-ready “Multi-Tool” for the rail industry.

Use cases

Maintenance (Diagnostics, Quality assurance, Troubleshooting)

Commissioning

Why choose Twin Train Workshop?

Testing of different components and systems with one test system

The TwinTrain-Workshop allows testing of various rail components and systems using a single, flexible platform. It simplifies the process by adapting to different components with minimal setup, ensuring efficient and consistent testing.

Can be combined with specific test solutions for end-to-end testing

It can be integrated with dedicated test solutions to enable complete end-to-end testing. This ensures seamless validation across entire systems and components within a unified testing environment.

Quality assurance through low-threshold testing

Quality assurance is ensured through low threshold testing procedures that are easy to implement. This approach allows for early detection of issues, improving reliability and reducing maintenance efforts.